Top wooden office visitor chair company—ergonomic & durable?

Inside the wooden visitor-chair scene: hardware that quietly makes or breaks comfort

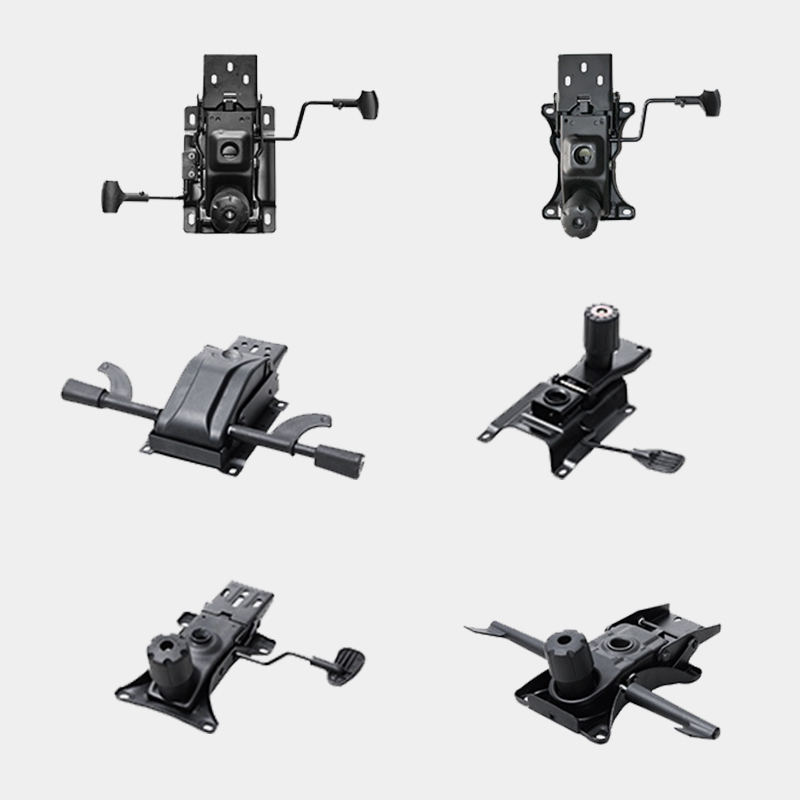

If you’re hunting for a dependable wooden office visitor chair company, here’s a slightly underreported truth: the hardware under the seat often matters more than the wood species on top. I’ve spent years visiting factories from Anji to Foshan, and—surprisingly—the best visitor chairs borrow a page from task seating: stable base trays, reliable tilt, and quiet lifters. The product I’m looking at today is the “Office chair base tray accessories, square handle adjustable rotary lifting mechanism.” It’s made in Tangpu Industrial Park, Anji Economic Development Zone, Zhejiang. That region’s basically the Silicon Valley of seating, only it smells faintly of varnish and freshly cut ash.

Industry trend check

Visitor seating is shifting toward hybrid builds: warm wood frames up top, rugged steel mechanisms below. Designers love the hospitality look; facilities teams want BIFMA-grade stability. Many customers say they’re tired of “pretty chairs” that squeak after three months. So the better wooden office visitor chair company teams now specify modular spares—mechanism, castors or glides, mesh/fabric choices, base colors, seat cushion density, backrest geometry, even armrest height blocks—so repairs don’t require landfill trips.

How the mechanism fits a wooden chair

The square-handle rotary lifting mechanism mounts beneath a plywood or solid-wood seat pan. In meeting rooms, a subtle 0–15° tilt helps posture during long briefings; in reception areas, the lift lets mixed-height guests sit comfortably. To be honest, not every visitor chair needs lift—some spaces prefer fixed-height elegance—but when you add it, the perceived value jumps.

Product specifications (key parameters)

| Parameter | Spec (≈, real-world use may vary) |

|---|---|

| Seat plate steel | SPCC cold-rolled, ≈2.8–3.0 mm |

| Hole spacing | 150 × 200 mm (common wooden seat pan pattern) |

| Tilt range / lock | 0–15°, multi-position lock |

| Lift stroke | ≈80–120 mm (gas-lift dependent) |

| Socket compatibility | Standard gas lift, cone mount |

| Max user load | 120–135 kg typical |

| Finish | Powder-coat, 240–320 h salt-spray option |

Process flow and testing

Materials: FSC-certified ash/oak frames (typical for the wood part), SPCC steel mechanism, Class-3/4 gas lift, high-resilience foam (45–55 kg/m³). Methods: CNC cutting for wood, hot-press plywood seat pan, stamping + robotic welding for mechanism, shot-blast and powder-coat, oven cure. Testing: BIFMA X5.1 seat/tilt cycles (≥100,000), static load ≥1,100 N on back, gas-lift leakage test, and 240–320 h neutral salt spray on coated parts. Service life: ≈8–10 years in office use, honestly longer in meeting rooms with lighter turnover.

Applications and customization

- Reception and lobby seating (silent tilt, optional glides instead of castors)

- Meeting rooms and training areas (easy height tweaks for shared tables)

- Education and municipal spaces (simple field-replacement of spares)

Custom options: mechanism, castor or glide, mesh & fabric, base color, seat cushion density, backrest style, armrest blocks. The better wooden office visitor chair company builders also color-match powder coats to veneer tones—tiny detail, big visual payoff.

Vendor comparison (snapshot)

| Vendor | Core strength | Certs | MOQ | Lead time | Customization |

|---|---|---|---|---|---|

| Anji-based mechanism maker | Stable rotary/tilt, spare ecosystem | ISO 9001, BIFMA parts test | ≈100 pcs | 15–25 days | High (handle, stroke, finish) |

| Regional assembler | Fast chair kitting | ISO 9001 | ≈50 pcs | 7–14 days | Medium |

| Premium EU supplier | Top-tier finishes | EN 1335, FSC | ≈25 pcs | 25–35 days | High |

Mini case study

A co-working brand in Singapore swapped fixed visitor chairs for wood-frame seats with this rotary lifting mechanism. Result? Fewer “too low for the table” complaints, and—according to their FM lead—maintenance dropped because spare parts (mechanism, armrests, seat cushions) could be ordered individually. They cited smoother swivel and zero wobble after six months. Not scientific, but it lines up with lab data.

What to ask your supplier

- BIFMA X5.1 and EN 1335 test reports for the assembled chair

- Salt-spray hours on metal parts; powder spec

- FSC chain-of-custody for wood; VOC data on finishes

- Service life estimate and spare-part availability window (5–7 years is decent)

Bottom line: a solid mechanism turns a nice wood chair into a professional tool. When you’re shortlisting a wooden office visitor chair company, look under the seat first.

References

- BIFMA X5.1: General-Purpose Office Chairs – Tests.

- EN 1335 Office furniture – Office work chair.

- ISO 9001: Quality Management Systems.

- FSC Chain of Custody Certification.

share:

-

Chairs Meeting Room: The Ultimate Guide to Choosing Ergonomic, Sustainable SeatingNewsNov.24,2025

-

The Global Appeal and Practical Benefits of Blue Meeting Room Chairs | Laining GlobalNewsNov.23,2025

-

Black Meeting Room Chairs: Durable, Ergonomic & Stylish Seating for Modern WorkspacesNewsNov.23,2025

-

Stackable Meeting Room Chairs - Durable, Efficient & Space-Saving SolutionsNewsNov.22,2025

-

Office Meeting Room Chairs – Comfort, Durability & Sustainability in Modern OfficesNewsNov.22,2025

-

Choosing the Best Office Chairs for Meeting Rooms: Comfort Meets StyleNewsNov.22,2025

-

Optimizing Office Spaces: The Essential Guide to Meeting Room Table and ChairsNewsNov.21,2025