Our development team, leveraging profound expertise, meticulously crafts over three ergonomically designed chairs annually, ensuring your final design is precisely transformed into a production mold.

Our production process integrates meticulous wood cutting and high-precision mechanical punching, ensuring the fine craftsmanship of our products.

Our chair fabric is meticulously sewn and precisely cut, complemented by comfortable cushion finishes, ensuring both comfort and aesthetic appeal of our products.

We stock 320 sets of finely crafted chair components to cater to the exclusive needs of customers for customized designs.

Every new design must pass BIFMA testing before being introduced to the market. Our equipped BIFMA testing center will provide comprehensive testing services to ensure that your product meets industry standards.

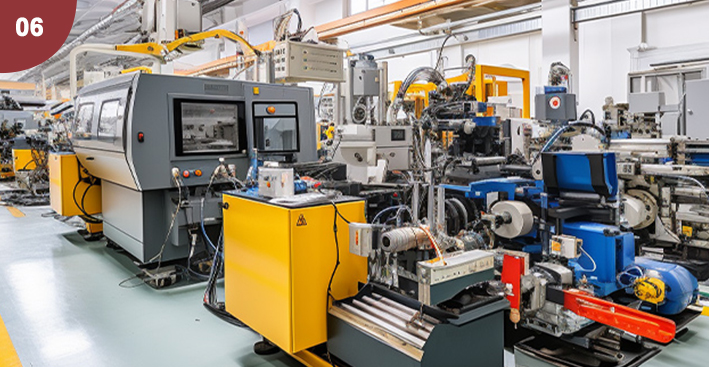

Our manufacturing base is staffed with over 150 skilled workers and is equipped with a 30,000 square meter modern workshop, five efficient production lines, and two advanced automatic welding robots. Notably, we have 12 fully automatic injection molding machines, which are key to our monthly production capacity of up to 40,000 chairs.

We have a modern, large-scale warehouse covering 5,000 square meters, with the capacity to simultaneously accommodate storage for over a hundred containers.