ergonomic fabric office chair factory

The Rise of Ergonomic Fabric Office Chairs A Factory Perspective

In recent years, the importance of comfort and ergonomics in work environments has become increasingly recognized. With many people spending long hours at their desks, the demand for ergonomic office chairs has surged. Among these, fabric office chairs are gaining popularity for their blend of comfort, aesthetics, and practicality. This article explores the significance of ergonomic fabric office chairs and the role of factories in their production.

Understanding Ergonomics in Office Furniture

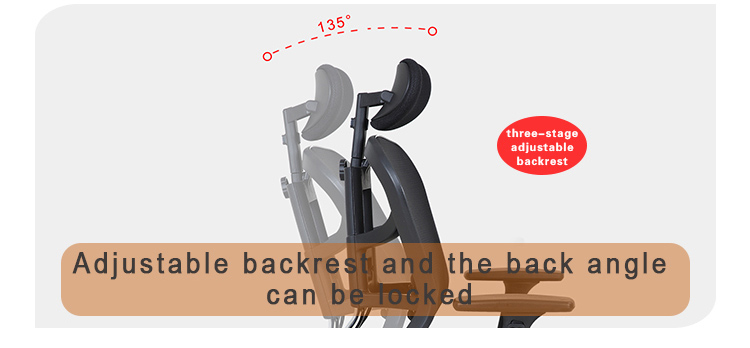

Ergonomics refers to the science of designing the workspace to fit the user’s needs. It emphasizes comfort, efficiency, and safety, advocating for furniture that reduces strain on the body. An ergonomic office chair is designed to support proper posture, allowing users to work comfortably for extended periods. Key features of ergonomic chairs include adjustable seat height, lumbar support, armrest adjustments, and breathable fabric.

Why Choose Fabric Over Other Materials?

Fabric office chairs offer several advantages over leather or synthetic alternatives. Firstly, they are often more breathable, which is crucial in preventing discomfort during long working hours. The fabric allows for better air circulation, helping to regulate body temperature. Additionally, fabric chairs come in a variety of colors and patterns, enabling companies to maintain a consistent aesthetic that aligns with their branding.

Moreover, many modern fabric chairs are treated with stain-resistant coatings, making them practical choices for busy workspaces. This durability extends the chair's lifespan and reduces the frequency of replacements. As a result, fabric office chairs often strike a balance between comfort, style, and cost-effectiveness, making them a favorite among both employees and employers.

The Role of Factories in Production

ergonomic fabric office chair factory

The manufacture of ergonomic fabric office chairs involves a complex process that combines technology with craftsmanship

. Factories play an essential role in ensuring quality, durability, and comfort in their products. A typical production process starts with the design phase, where ergonomists and designers collaborate to create prototypes that undergo rigorous testing.Once a design is finalized, factories employ advanced machinery for cutting, sewing, and assembling the different components of the chair. Automated cutting machines ensure precision, while advanced sewing machines facilitate efficient production. Furthermore, factories often utilize sustainable practices, sourcing eco-friendly materials and minimizing waste.

Quality control is another critical aspect of the manufacturing process. Factories consistently test finished products to meet industry standards and client specifications. This commitment to quality not only enhances customer satisfaction but also builds the factory’s reputation in the competitive market.

The Future of Ergonomic Office Chairs in Factories

As awareness of workplace wellness continues to grow, the demand for ergonomic fabric office chairs is expected to rise. Factories will need to adapt to this changing landscape by investing in innovative designs and sustainable production methods. In addition, incorporating technology, such as smart sensors for posture correction, could revolutionize the ergonomic chair market.

Moreover, as remote work becomes more common, the focus on home office ergonomics will prompt factories to cater to individual consumers. This may lead to a greater variety of styles and price points, ensuring that ergonomic solutions are accessible to everyone.

Conclusion

The significance of ergonomic fabric office chairs cannot be overstated in today’s work environment. Factories play a pivotal role in their production, ensuring quality, comfort, and aesthetics are met to enhance employee well-being. As the market evolves, these factories will become increasingly important in shaping the future of office furniture, helping to create healthier workplaces for all.

share:

-

Multi Colored Modular SofasNewsJul.07,2025

-

Enhance Seating Experience with Chair AccessoriesNewsJul.07,2025

-

Enhance Four Legged Chairs with WheelsNewsJul.07,2025

-

Elevate Your Workspace with Luxurious Boss ChairsNewsJul.07,2025

-

Discover Comfort of Compression SofaNewsJul.07,2025

-

Training Chairs Aim To Provide A Fully Functional And Flexible Workspace For Various Training, Educational, Or Collaborative ActivitiesNewsJun.06,2025

-

The Big Boss Office Chair Aims To Provide Comfort And Support For Individuals In Management Or Leadership PositionsNewsJun.06,2025